1

2

3

4

5

6

1

Milk treatment

– Milk receiving module

– Heater

– Pasteurizer

– Dégazeur

2

Specific equipments

– Homogenizer

– Centrifuge (cream separator, bactofuge, clarifier)

– Online standardization module

3

Energy modules

– Steaming station

– Overheated water

– Clean steam

– Air stérile

4

Custom skids

– Automatic Manifold

– Injection of ferments

– Hot water loop

5

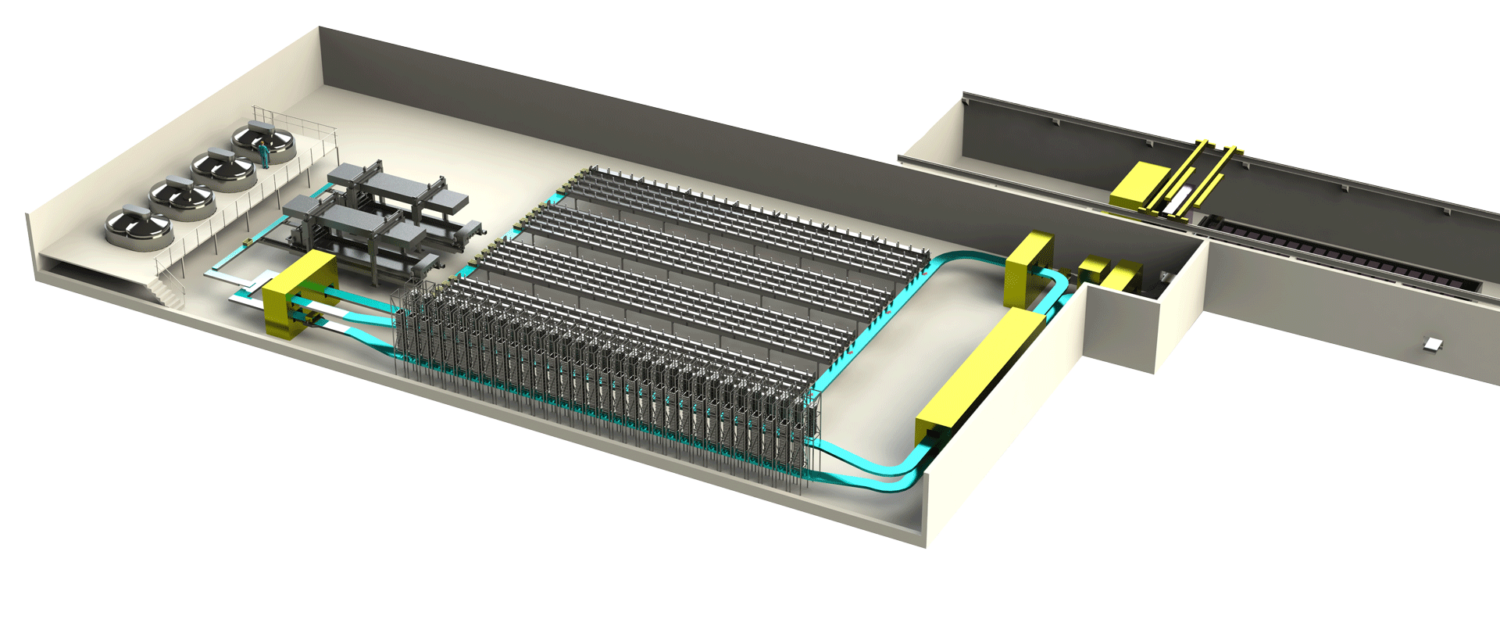

Distribution rack

– Process

– Fluids and energies

6

Storage

– Vat not agitated, agitated

– Ultra-clean Vat

– Sterile Vat

1

2

3

4

5

6

7

8

9

10

1

Production vats

– Open or closed vat

– Cuve double O ou oblongue

– Cuve statique ou basculante

2

Cutting line

– Cutting module

– Carpet or hopper

– Removal in molds

3

Moulding

– Carousel moulder EVOPRO GME 100

– Pre-pressing tank EVOPRO GME 500

4

Storage of molds and caps

– Vertical storage

5

Pressing

– Carousel press EVOPRESS ROTA 5000

– Online Press EVOPRESS IN LINE

– Pressing cabinet

6

Mold washer

– Washing tunnel

– Rotary washer EVOCLEAN ROTA 600

7

– Demoulding

– Turning station

– Unpacking

– Demoulding

8

Conveying

– Conveyor belt

– Motorized stainless steel roller conveyor

– Pesage (statistiques en ligne)

9

Brining

– Saumurage à chargement manuel

– Saumurage automatisé EVOBRINE

10

Means of access and security

– Passerelle inox

– Cartérisation