A French company

About us

About us

Who we are

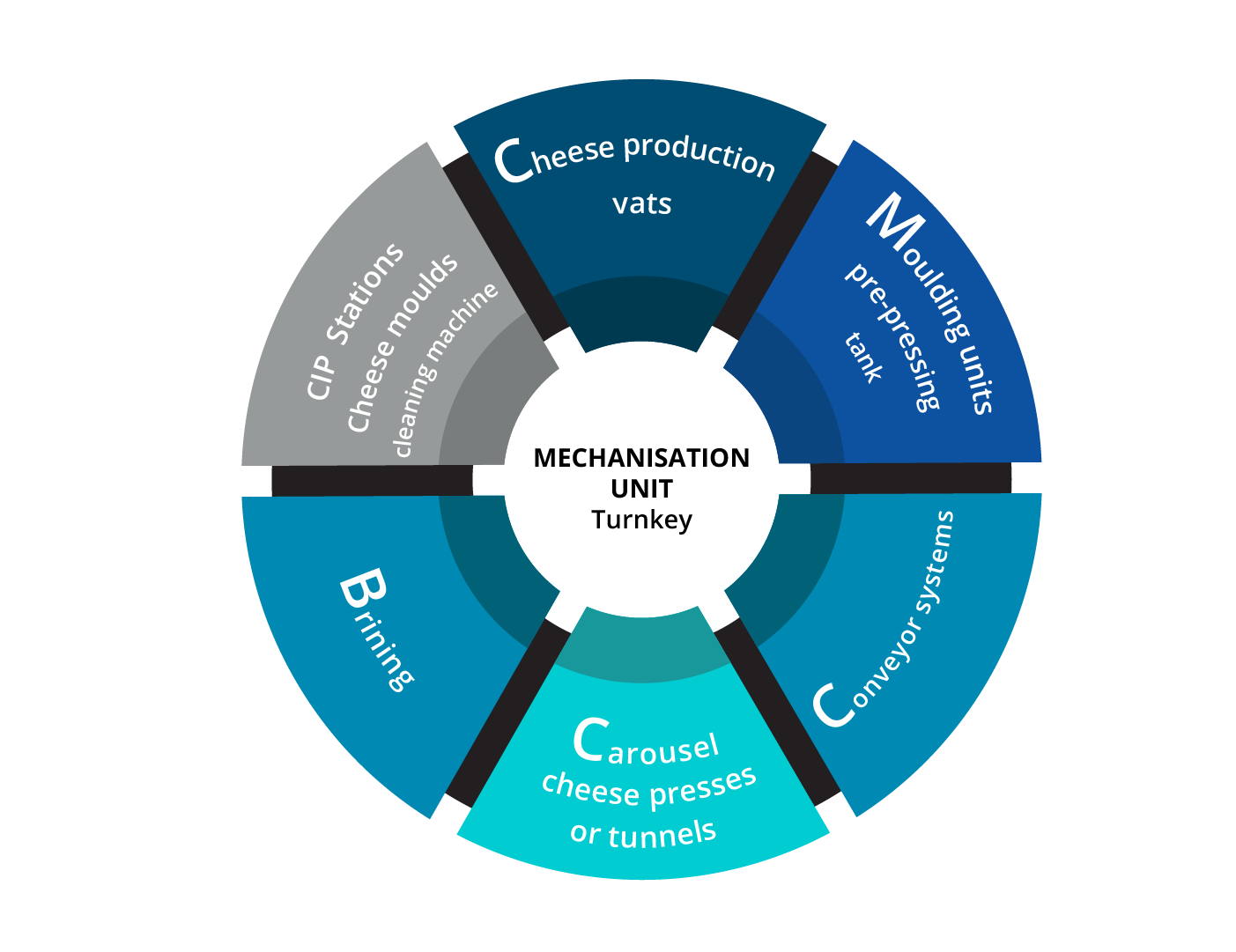

Specialists in cheese production technology for cooked and uncooked pressed cheeses, we provide process and mechanisation solutions for the cheese production industry: milk and whey processing, coagulation vats, moulding, pressing, brining and CIP cleaning systems. Joining the Steap Stailor group in 2018 means we are now equipped with the necessary expertise and resources to provide the design, construction, installation and maintenance of stand-alone machines or turnkey production lines.

Our multi-skilled teams, experts in cheese production technology, ensure that every stage of a project is well-managed and well-built, in line with the group’s principles of rigour, quality and service.

Historically located in the heart of Franche-Comté (France), a region renowned for its exceptional PDO cheeses, the company has developed its expertise around local heritage, cheesemaking traditions and state-of-the-art technology. With a strong presence in France, we have expanded our operations worldwide, contributing to the influence of France’s recognised excellence in the cheese production industry.

Steap Stailor Group

A French company

Steap Stailor group is a French family-owned SME that has its origins since 1980. As a specialist in processing processes in the agri-food, health and biotechnology industries, the group is developing and diversifying its fields of expertise in order to position itself as a leader in the field of industrial integration in France and abroad.

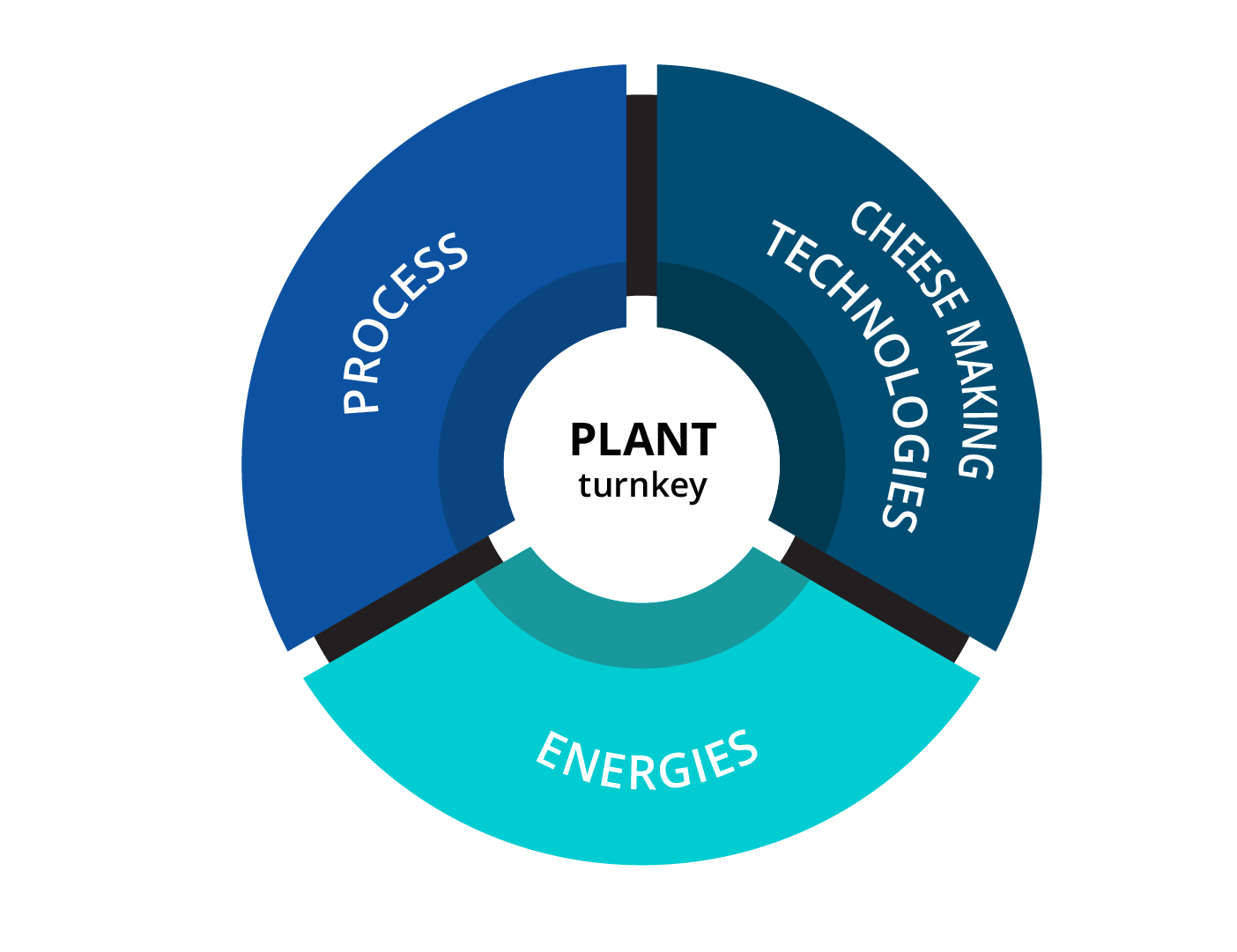

With the diversity of our offer, Steap Stailor Group is able to ensure the complete realization of a cheese facility by the association and coordination of each of the companies based in the French territory that make up the group :

- Steap Stailor – Process integration : Milk and whey processing

- Evoli – Specialist in cheese production technology : Mechanisation

- Citec - Fluid and energy integrator: Generators and energy distribution

A French company

An international influence

Steap Stailor, based in Grenoble (Rhône Alpes – France), specialises in liquid and semi-liquid processes. Well-established with a local network of 4 sites (Grenoble, Metz, Rennes, Tarbes – France), Steap Stailor is the guarantee of high-quality design and installation for milk processing systems, and with this contributes to the quality of Evoli equipment.

Citec, based in Rennes (Bretagne – France) and founded in 2000, joined the Steap Stailor group in 2012. Specialists in the design and construction of industrial projects using energy distribution (compressed air, clean steam or industrial steam, iced water or glycol, water treatment etc.), Citec lends its extensive expertise to building energy devices for the cheese production industry.

Driven by the group’s synergy, Evoli confirms its position as a market leader by proposing turnkey solutions in France, Europe and elsewhere around the world, supported by the group’s international network :

- Steap Stailor Africa | Casablanca – Morocco

- Steap Stailor Russia & CIS | Moscow – Russia

- Steap Stailor South America | Campinas – Brazil

Steap Stailor Siège

6, rue Docteur Schweitzer

38180 Seyssins

FRANCE

Steap Stailor Sud-Ouest

Rue de la ZA de la Porte de la Bigorre

65140 Rabastens de Bigorre

FRANCE

Steap Stailor Nord-Est

8, rue Théodore Monod

Zone ECOPARC Nord

57140 Norroy Le Veneur

FRANCE

Steap Stailor Nord-Ouest

7, rue du Pré du Bois

35000 Rennes

FRANCE

Evoli

4, rue Champenâtre

ZA Eurespace

25770 Serres-Les-Sapins

FRANCE

Citec

7, rue du Pré du Bois

35000 Rennes

FRANCE

Steap Stailor Africa

469, Avenue Ambassadeur Ben Aicha

Roches Noires

20290 Casablanca

MOROCCO

Steap Stailor Russia / France Process

Moscow, 129090

Shepkina Street 28

Office N°506

RUSSIA

Steap Stailor South America

Rua Baguaçu, 26

Sala 402

13098-326 Alphaville Campinas / SP

BRAZIL

Registered patents

Specialised design departments for each pole of expertise

The cheese industry of the future

Innovation

Whilst honouring cheesemaking tradition but with a firm focus on innovation, with no less than 7 patents to date, we provide solutions for the cheese industry of the future.

We have focused on the development of patented innovative solutions for 2 machines :

- A moulding unit in the GME series with a nominal capacity equivalent to the production of 12 Comté type cheeses in 10 minutes. The innovative features of this machine include the ability to adjust the size and type of mould using 12 invertible mould extensions, as well as the ability to obtain precision moulding to form consistently shaped curd loaves. The design of the GME machine can be adapted to production capacity or mould format.

- A fixed carousel press with enclosed sides and equipped with a central automated robotic arm for loading and unloading. This machine loads the demoulded cheeses onto the press columns and then unloads them for a fully automated system.

High-performance and innovative solutions, created by Evoli’s Research and Development department, are also available for each stage of the production line including pressing, conveyoring, weighing and cutting.

France & Europe

Evoli

4, rue Champenâtre

ZA Eurespace

25770 Serres-Les-Sapins

FRANCE

+33 (0)3 81 60 56 80

evoli@evoli.fr

France & Europe

Steap Stailor France

6, rue Docteur Schweitzer

38180 Seyssins

FRANCE

.

+33 (0)4 76 84 29 70

steapstailor@steapstailor.com

Africa

Steap Stailor Africa

469, Avenue Ambassadeur Ben Aicha

Roches Noires

20290 Casablanca

MOROCCO

+212 (0) 5 22 24 88 76

j.hajjoubi@steapstailor.com

Russia & CIS

Steap Stailor Russia / France Process

Moscow, 129090

Shepkina Street 28

Office N°506

RUSSIA

+7 495 684 90 05

office@fprocess.ru

South America

Steap Stailor South America

Rua Baguaçu, 26

Sala 402

13098-326 Alphaville Campinas / SP

BRAZIL

+55 (19) 3262-2161

g.pellegrini@steapstailor.com