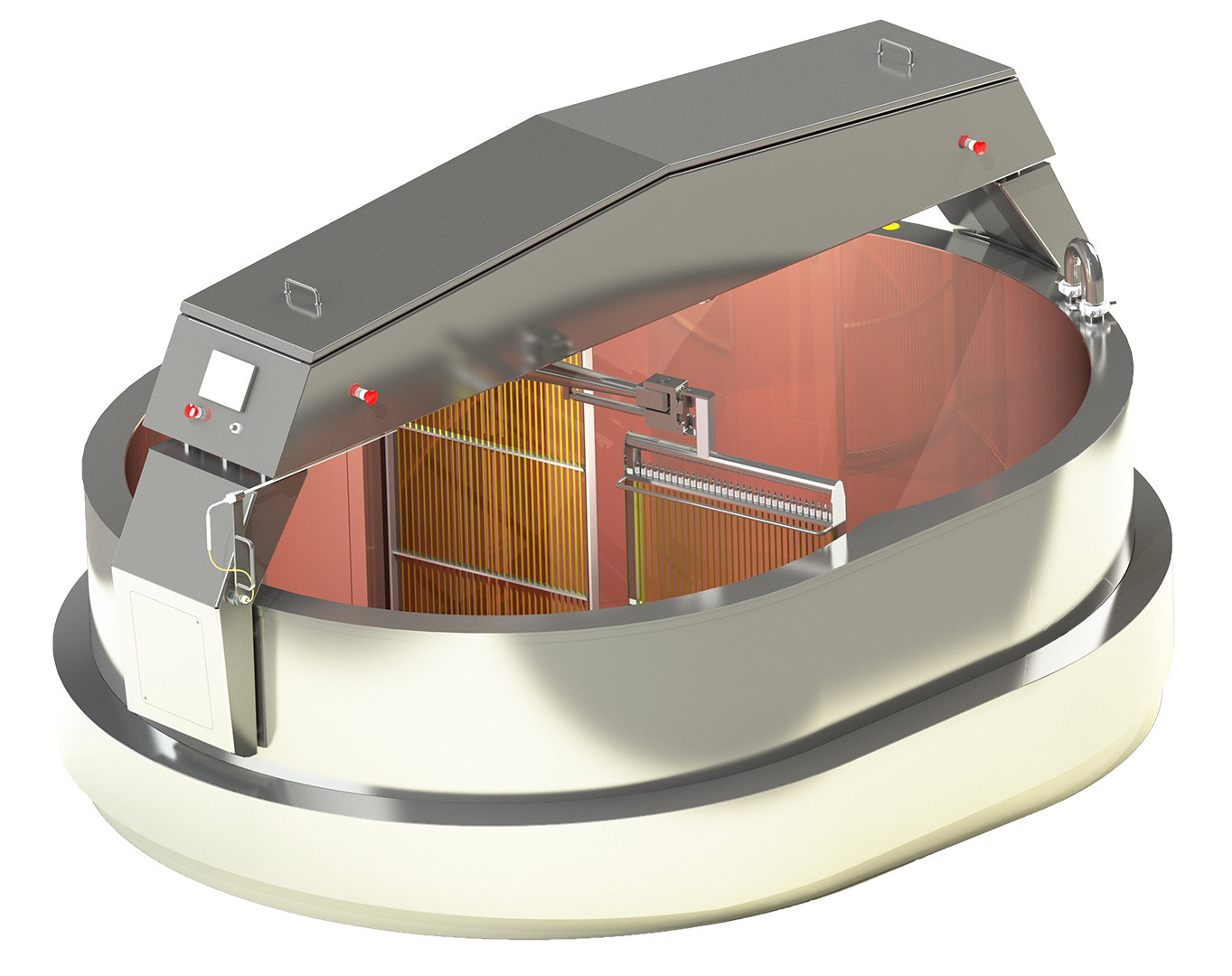

Cheese production vats

We provide a comprehensive range of cheese vats for the production of cooked and uncooked pressed cheeses. These vats are designed for stirring, heating, cooling, coagulation and as an option whey separation (several options available).

Two designs are available :

- An open vat made with stainless steel or copper walls available as a round or “double O” design with a capacity of 300 to 8,000 litres.

- A fully automated closed vat made with stainless steel walls and a “double O” design with a capacity of 1,000 to 18,000 litres.

Our cheese vats, made in our workshops in Besançon (Franche Comté – France), are carefully designed and built to deliver optimum efficiency in terms of thermal exchange, mechanical resistance and cheese yields. Our curd cutters are designed with stainless steel wires or blades for optimal precision.

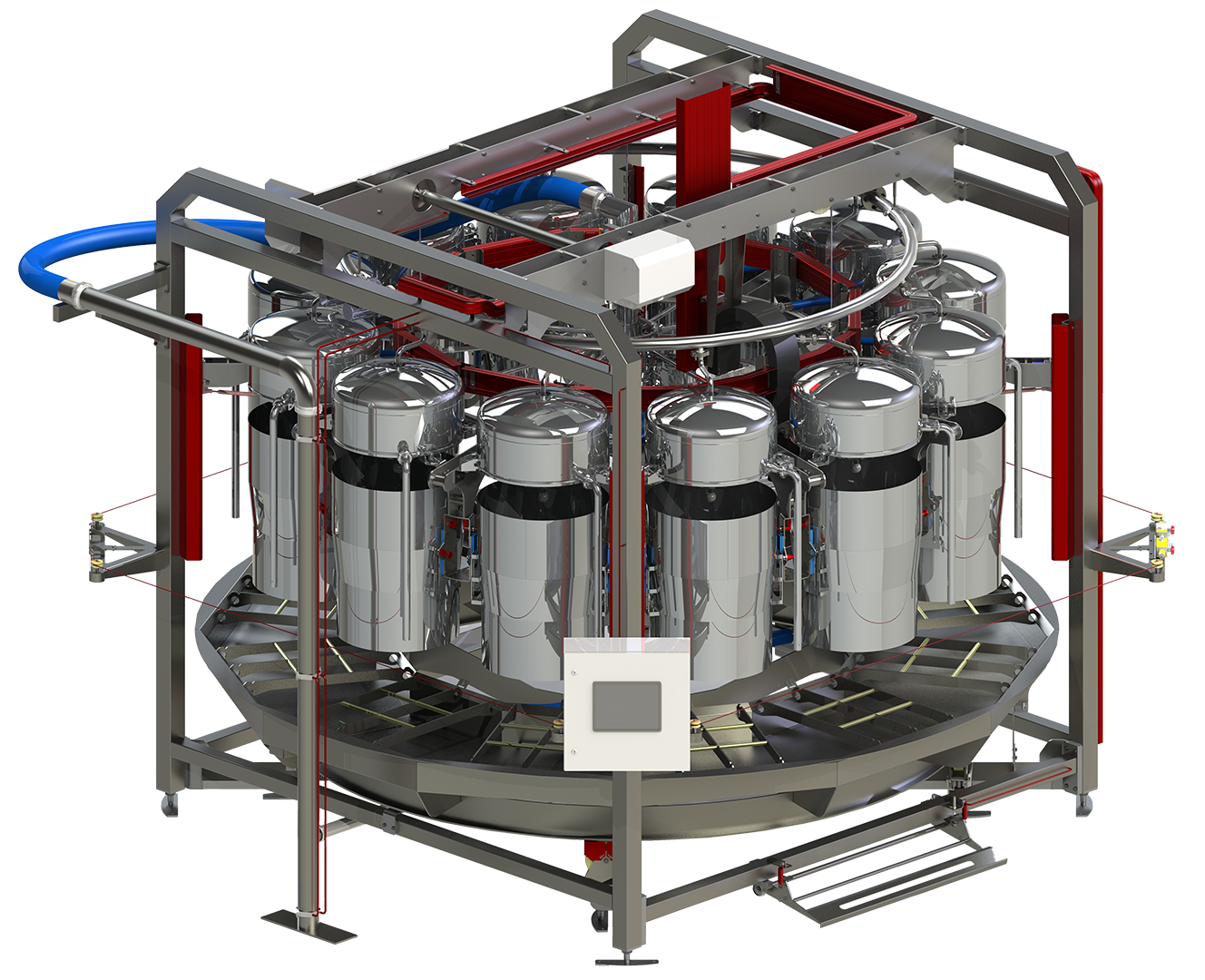

EVOPRO GME 100

Evoli moulding units (patented model)

EVOPRO GME 100 is the first of Evoli’s moulding units This patented model is entirely designed and built in our workshops in Besançon (Franche Comté – France). These moulds are designed for round cooked and uncooked pressed cheeses, covering a range of diameters from 400 mm to 900 mm.

EVOPRO GME 100 is a carousel-shaped machine fitted with mould extensions. The circular layout of the mould extensions ensures the curds are well-distributed in the moulds.

EVOPRO GME 100 is available in 2 sizes: 8 or 12 mould extensions. It is also available as a fully automated machine with loading and unloading of moulds.

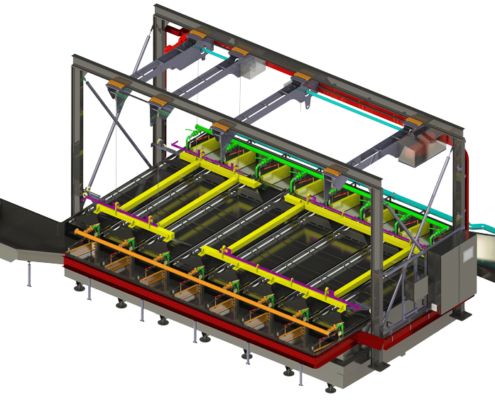

EVOPRO GME 500

EVOPRO GME 500 is the second of Evoli’s moulding units. A product of our latest innovation, it is entirely designed and built in our workshops in Besançon (Franche Comté – France). Designed for the industrial production of pressed cheeses, it offers a moulding capacity equivalent to 300 tonnes of milk per day. Equipped with an innovative cutting and weighing action, this moulding unit makes managing format and weight easier and more flexible.

The whey is drained off into a draining tray and the curd is pre-pressed using a fully automatic system. The blocks of curd are sliced, ejected and moulded according to the recipe pre-programmed by the operator. The machine checks the density of the blocks and their size can be adjusted if necessary.

EVOPRO GME 500 can mould different cheese formats and the equipment can be quickly reconfigured for each format. Cleaning is done using a CIP cleaning unit which can be used throughout the production process.

EVOPRESS ROTA 5000

The EVOPRESS ROTA 5000 carousel cheese press is available in a range of designs: manual, semi-automatic or fully automatic. It is ideal for large cheeses. The automatic version is equipped with a central robotic arm, and the carousel press allows for the stacking and unstacking of cheeses in circular columns. Fully enclosed, the press can be CIP cleaned using a central CIP machine or a high-performance integrated cleaning system. It is also designed to continuously drain the whey.

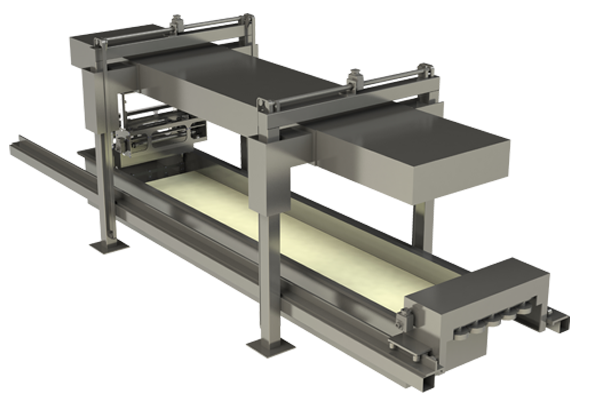

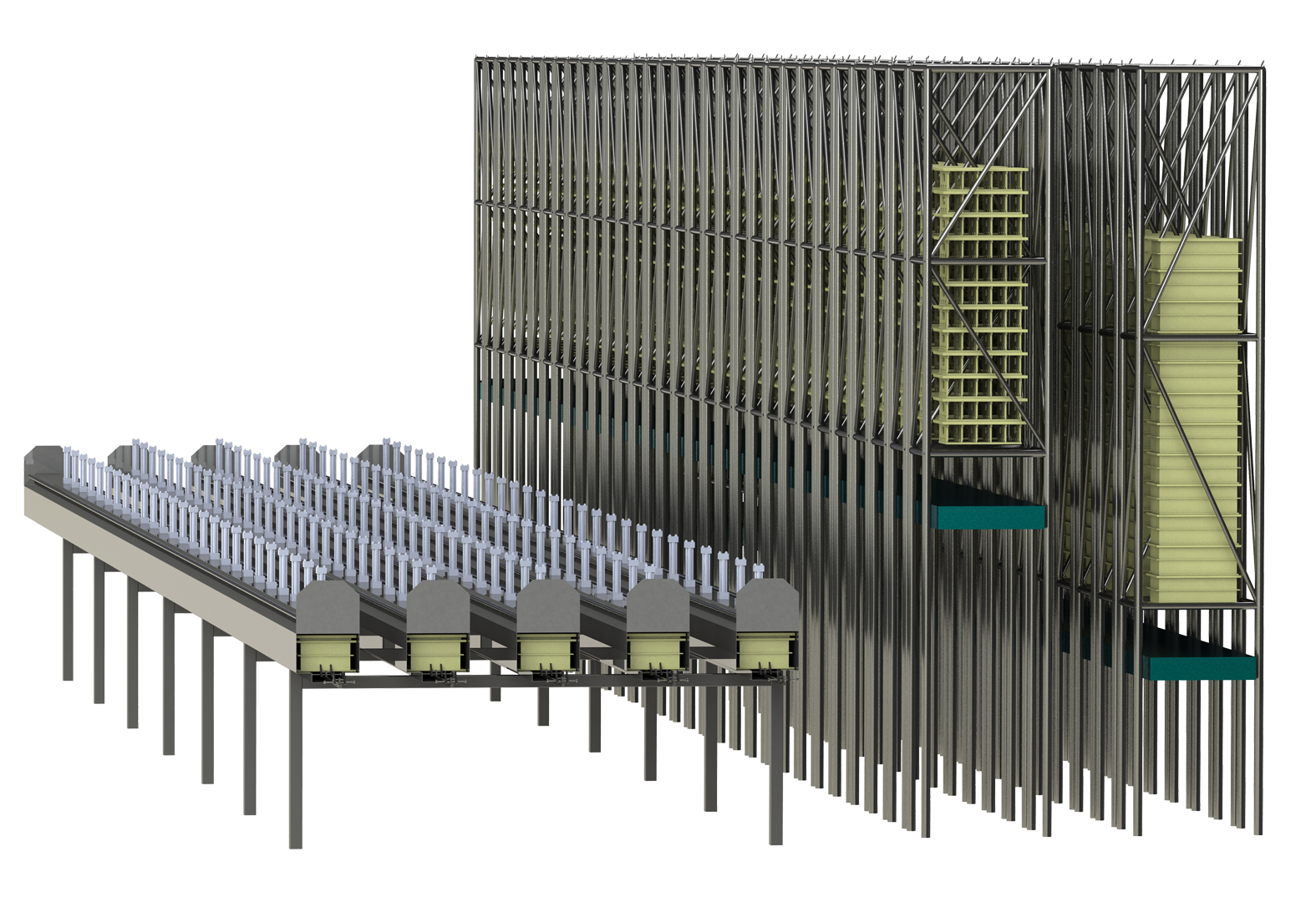

EVOPRESS IN LINE

The EVOPRESS IN LINE tunnel press is designed for large-scale production capacity. Based on a modular step-by-step design, the tunnel press machine developed by Evoli adapts to production capacity and the configuration of the production space. With a system of conveyors, mould storage and cleaning tunnels, the EVOPRESS IN LINE solution ensures a continuation of the production line between moulding and brining. Fully enclosed, the press can be CIP cleaned using a central CIP machine. It is also designed to continuously drain the whey.

Brining

EVOBRINE

EVOBRINE brining solutions are available in a range of different models, from the manual loading of brining basins via hoist to the installation of a fully automated system. Its system of conveyors mean it can be easily incorporated into the production process before pressing, and brining basins can be equipped with an automated double rail system managing the loading and unloading of cheeses on racks. These solutions also integrate the cleaning of cheese racks via specially designed cleaning chambers.

Cleaning

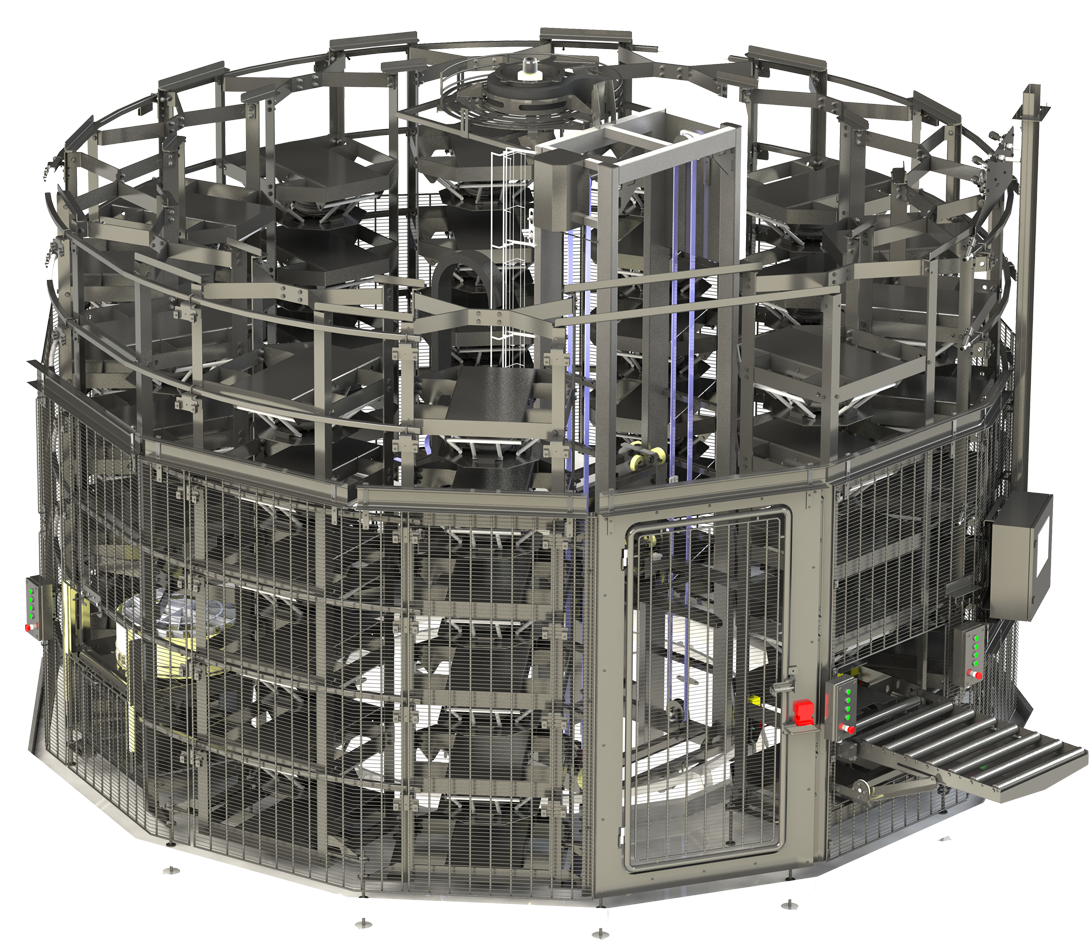

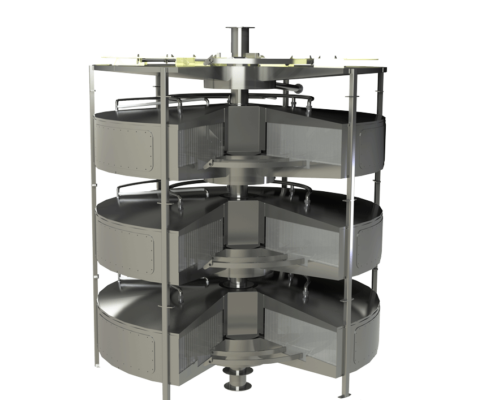

EVOCLEAN ROTA 600

The rotary cleaning machine EVOCLEAN ROTA 600 is a new cleaning machine designed for cheese production, patented by EVOLI. This machine cleans cheese moulds more effectively than a traditional cleaning machine with an optimised consumption of water, detergents and energy.

Its circular design means it can easily be incorporated into existing facilities. The machine consists of modular sections stacked one on top of the other to allow for optimal cleaning space. There are no mats and the specific position of the cleaning nozzles allows for optimum mechanical cleaning particularly useful and effective for micro perforated moulds. The design of the EVOCLEAN ROTA 600 rotary cleaning machine allows the moulds to be separated from the lids as they enter the machine, these then leave the machine via two separate channels for a more streamlined process.